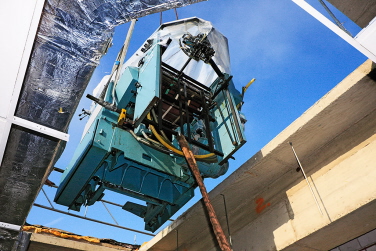

New printing press at the Department of Design – spectacular crane transport over the university roof

(mk) Spectacular views at the Department of Design: Whilst the first semester students looked forward with anticipation to their future studies at the traditional welcoming event in Audimax on the morning of 21st September, the Department's staff were at least as excited: This reason was that a brand new offset printing press was delivered on that morning, right on time for the start of the semester. This will open up previously undreamt of design options and technical opportunities for the design students in their state-of-the-art applications.

As such a large, heavy machine obviously could not be simply moved into the printing room via the goods lift, even the logistics preparations were imposing. A heavy-duty crane had to be hired for the purpose, which started work by lifting three concrete slabs from the flat roof on Josef-Gockeln-Strasse. This alone required precise coordination between the special vehicle operator, those responsible in the faculty and the technical service staff because the weight of the ceiling slabs varied somewhere between 300 kilos and a ton. The crane's hoisting chains had to be sufficiently dimensioned to ensure that these did not buckle and drop and break the concrete slabs. Some sections of the B-tract had to be cordoned off for reasons of safety and to avoid all possible risks. Once the slabs had lastly been lifted out without problem and provisionally stacked on the roof, the old printing press was able to be lifted out through the now open ceiling, offering spectators and casual passers-by a stimulating spectacle certainly not seen everyday. Yet it was not only stimulating, but definitely also nerve-jangling for the responsible technicians and logistics experts: The work had to be accurate to the millimetre due to the pipes laid on the ceiling – and this twice, of course: After the old printer had been lifted out by the crane, the new press – with a total weight of around 8,500 kilos – then had to be hoisted in...

Yet Hans-Joachim Wolter, who will attend to the machine as a member of the faculty's staff in the graphic workshop, believes that the effort was worthwhile: "We've now got an ultra-modern system in the Speedmaster SM 52-4, one that is perfectly suited to meet the needs of the Faculty of Design working with a wide range of different media!" In contrast to the old monotone printer which could only print one colour per print pass, the new model from Heidelberger Druckmaschinen AG has four-colour capability, so that all jobs can be printed out in one run. A much wider range of materials can now be printed than before. This not only includes all sorts of paper, but also OHP-foils. Other special features include a modern colour control desk that enables colour stages to be adapted individually, a fully automatic reversing unit for precise turning of pages, a speed-compensated damping unit which guarantees high colour brilliance and fast drying plus a constant dye temperature. Thus another reason for first year students to look forward to their studies with anticipation and to the print-outs they create there.